Over the last few years, Filame has been investing in its 3D printing capabilities, in particular for the production of tooling for the manufacture of strip metal product prototypes. This strategy allows us to strongly reduce the costs hereof while increasing the speed of manufacturing. Filame is pursuing its strategy in this area.

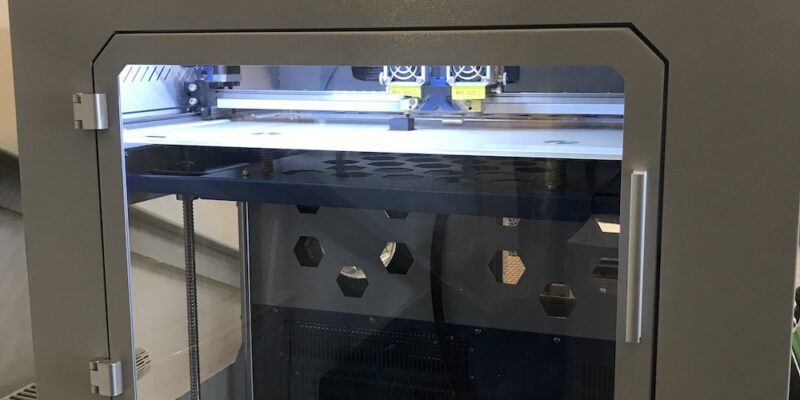

Thus, as part of the development of its rapid tooling creation capabilities for serial products, but also to strengthen its prototyping capacity, Filame has just expanded its capabilities with the acquisition of a Creabot F430 3D printer.

In addition to a greatly increased printing speed, this printer especially works with new materials* whose main advantage is their hardness.

This means that Filame can now not only 3D print prototyping tools, but also production tools for small series (e.g. bending blades). In addition, the Creabot F430 allows for the production of more complex prototypes, the production of highly precise inspection jigs and even the production of spare parts for our machine park.

As such, the extension of the 3D printing capacities provides Filame with the capacity to offer these productions at more advantageous costs and with significantly higher dimensional precision (0.03 mm).

* (PLA – ABS – HIPS – PC – TPE – Nylon _ PETG – AS – PP – PVA – Glass fiber infused – Carbon fiber infused – Metal Fill – Wood Fill)