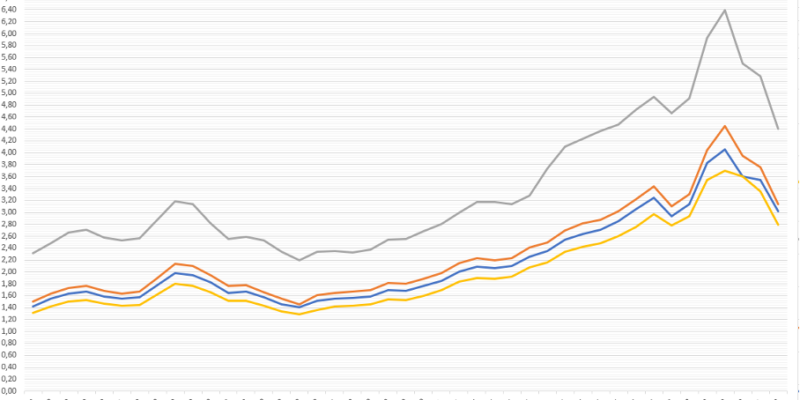

As the Filame Group does every month, we have consulted our panel of suppliers to provide the most accurate estimate possible of the evolution of the price of alloy extras for the stainless steel grades that the Filame Group uses on a regular basis.

In June, after the surge in May, we saw a drop in prices for the first time. The downturn continued slightly in July.

The decline continued in August.

This seems to reflect a decline in economic activity that began to be felt in June and which is due in particular to the various geo-political events. Economic activity in China has continued to decline and so has demand.

This movement does not mean that we will return to the prices that prevailed in 2019. Indeed, demand for nickel in particular remains very strong and is driven by the demand for this metal in the battery industry.

It should be noted that all suppliers still apply an energy surcharge to take into account the increased energy costs. This surcharge, in turn, continues to rise. The Russian gas crisis is likely to continue to exacerbate the pressure on energy prices.

As a result, the price of stainless steel will not fall in the same way as the price of alloy surcharge.

In addition, large users had hedged their bets during the very sharp increases in the first half of the year and have stocks and contracts to deliver at higher prices than they could obtain today in spot purchases.

Filame points out that the price of alloy surcharges is set month by month by the various suppliers according to the grades of stainless steel they offer. There are therefore differences between the various suppliers but the trend is noticeable for all of them.

Furthermore, the price is set on the day the material is delivered. There may therefore be differences between the time of ordering and the time of delivery, especially as delivery times have not decreased.

It should also be noted that the figures below are a general trend among steel manufacturers and that the price among slitters, wire drawers or wholesalers varies according to the quality requested, the nature of the product (sheet, coil, wire), the quantities requested, the thicknesses or diameters of the wire and the packaging.

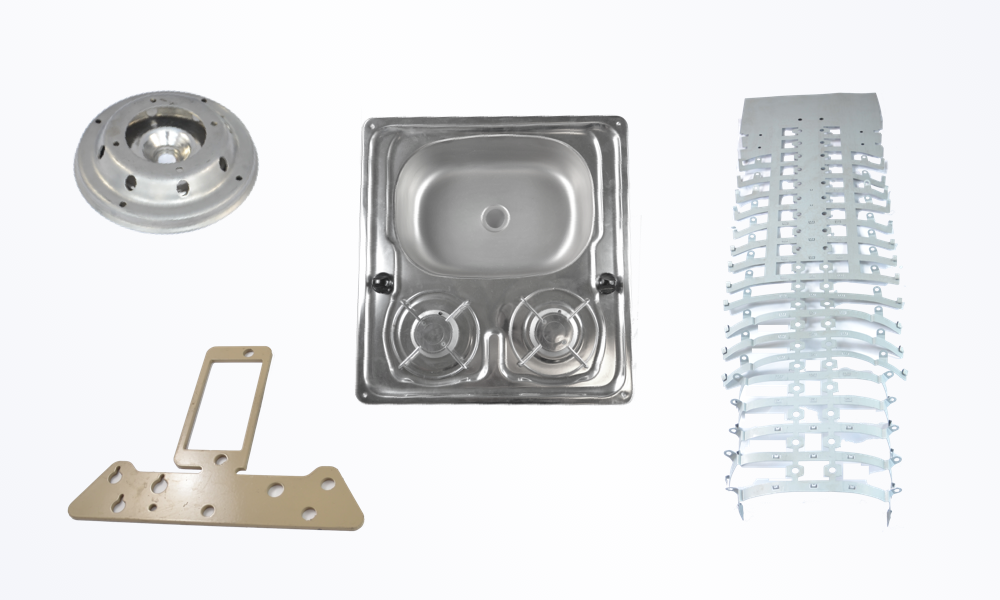

With over 20% of its turnover from civil engineering machinery, forklift & industrial vehicle, The Filame Group has extensive expertise with global and European leaders in these industries.

For this sector, Filame mainly manufactures a set of laser cut parts or mechanical press (shim, washer) and a set of sheet metal parts and welded assemblies. The Filame Group masters the wide range of the control and exigence systems needed for clients such as Caterpillar.

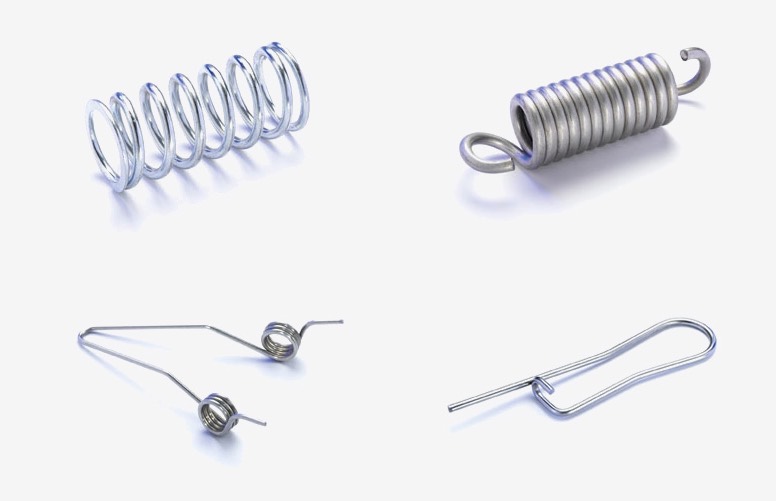

From the unit to several million pieces, Filame offers a comprehensive solution. Whether you are in a planning phase and need our expertise or already have your final plans and specifications, we are here to help you.