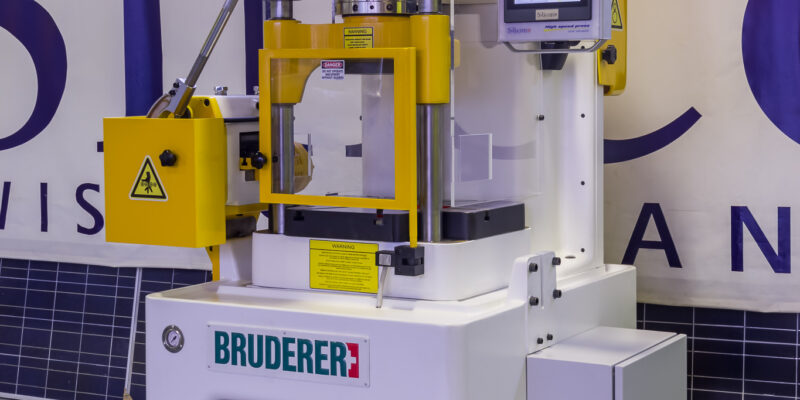

Filame has acquired 3 Bruderer BSTA 30 automatic high-speed presses.

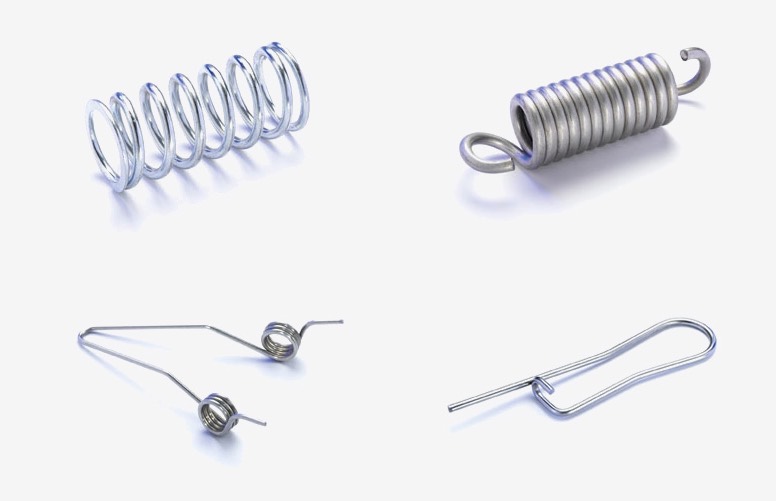

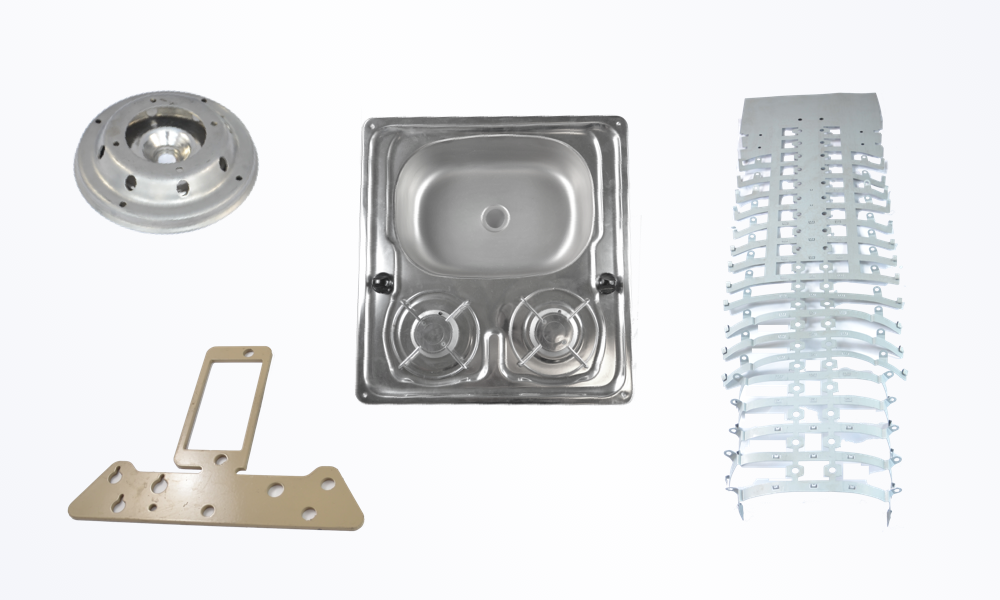

This acquisition enables Filame to significantly increase its production capacity for small parts in large series, particularly in the fields of automotive retaining parts (quickie washers, starlock ® washers, axle lock washers, Belleville washers, etc.), in steel or stainless steel, spring or non-spring quality.

Filame is thus confirming its position as a key player in these markets.

These Bruderer BSTA 30 presses have a capacity of 600 strokes per minute, which gives Filame a total production capacity of 108,000 parts per hour on its three presses.

Filame can, if required, equip these new presses with multi-pallet unwinders to increase the uninterrupted production time. Filame can also configure its presses with a waste chopper at the press exit or a belt rewinder, depending on the needs for speed and precision.

These Bruderer BSTA 30 presses, coupled with Filame’s specific know-how in the design and manufacture of precision tools for high-speed presses, and its existing fleet of presses in these fields, give Filame an unrivalled ability to meet all its customers’ production needs from small parts to very large series and in extremely short lead times.