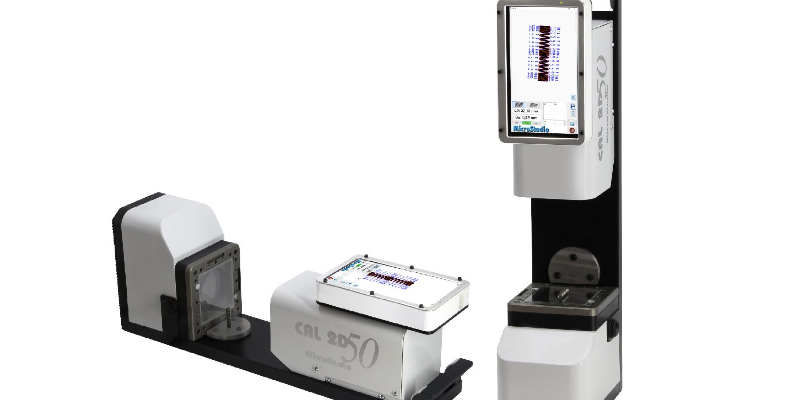

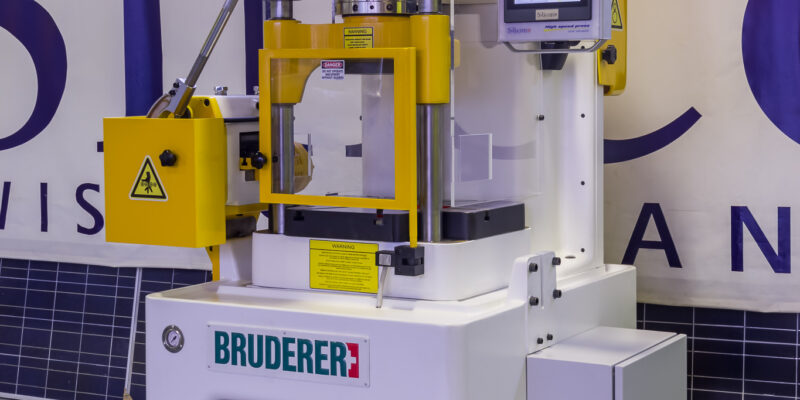

Filame specialises in the mass production of parts on automatic presses using multi-step tools.

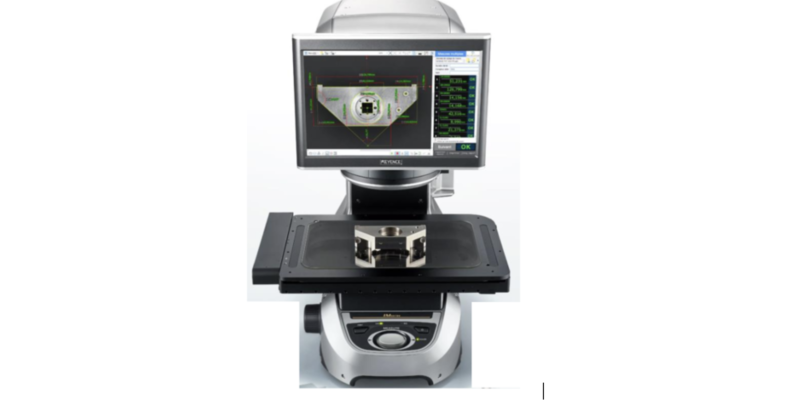

Filame’s Engineering Department designs, manufactures and maintains all the tools that Flame uses for its production. As a result, Filame has developed unique know-how that enables it to guarantee its customers the manufacture of the most complex parts, meeting the exacting quality requirements of sectors such as the automotive, defence, medical and aerospace industries, …..

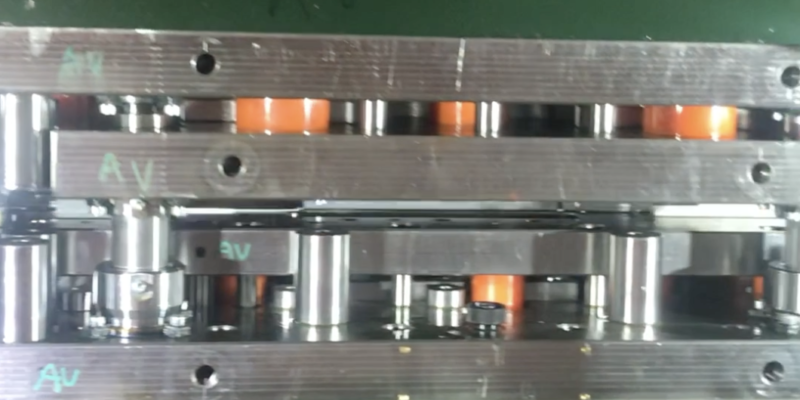

Filame developed an automatic press tool for a 125-tonne Haulick & Roos press for a major automotive assembly company. This is a 15-steps tool capable of producing 2 parts per stroke at a very high rate (12,000 p/h).

The parts are made of spring 301 stainless steel, 1.5 mm thick, and feature several oriented folds.

You can watch this realisation on this video.